Research Associate

Department of Information Engineering and Mathematics

University of Siena, Via Roma, 56 - 53100 Siena (Italy)

Tel: +39 0577 234850 EXT 1033

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Research Activities

ERC Sector PE5 - Synthetic Chemistry and Materials: Materials synthesis, structure-properties relations, functional and advanced materials, molecular architecture, organic chemistry

ERC Sector PE10 - Earth System Science: Physical geography, geology, geophysics, atmospheric sciences, oceanography, climatology, ecology, global environmental change, biogeochemical cycles, natural resources management

Publications

Check the updated publication list on the Google Scholar account.

Keywords

Electronic circuits, chemical synthesis, chemical sensors, sensor networks, air pollution, gas sensors, Metal Oxide Semiconductors (MOX), electronic nose

Very Short Bio

Francesco Bertocci was born in Pescia, Italy, on February 18, 1980. He received the M.S. degree in Electronic Engineering in 2007 and the Ph.D. degree in Industrial and Reliability Engineering in 2011 from the University of Florence, Italy. His current research interests are design and development of different chemical sensors and their characterization through electrical and electronic instrumentation and measurement.

Research interests:

- preparation and characterization of micro and nano materials for environmental gas sensors;

- thick film metal electrodes deposition on alumina substrate by semi-automatic screen printer and spin-coating machine;

- development and modeling of nano-structured sensors: data acquisition and elaboration;

- reliability, availability, maintainability and safety (R.A.M.S.) study of complex electro-mechanical systems;

- new sensors and actuators devices and technologies;

- characterization and analysis of new electrically conductive adhesives (ECAs).

His research activity started in 2006-2007 with the MS degree in Electronic Engineers “Experimental studies on the performance of electrically conductive adhesives for the realization of ultrasound probes”, carried out at the Laboratory of Measurements, Reliability and Quality – Electronics and Telecommunications Department and at Esaote SpA. With the assumption of Directive 2002/95/CE concerning the Restriction of certain Hazardous Substances (RoHS), it was needed the experimentation of various lead-free substances for the realization of solder joints in RoHS-compliance electric and electronic equipments. Initially, it was focused on the feasibility of achieving micro-solderings through electrically conductive adhesives (ECA) for electronic components and joints with fine pitch.

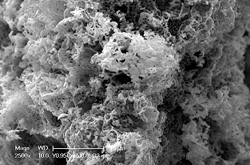

The mechanical and electrical performance analysis of novel silver ECAs has been implemented by means of thermal stress and vibration tests, arranging for qualitative characterization and their reliability. In particular, the study carried out during PhD course has focused on the electrical and mechanical analysis of ECAs by means of environmental scanning microscope (ESEM - Environmental Scanning Electron Microscope) and microanalysis (EDAX - Energy Dispersive X-Analyze ray), valid instrument for the analysis of the morphology and of chemical structure of ECAs. This novel soldering material has been taken into consideration in the design phase of ultrasound array transducer, which is the core of a linear phased-array probe, that is able to monitor the cardiac muscle. The aim was the characterization of the Tx/Rx channel in biomedical ultrasound probe developing a new validation procedure in order to identify the critical elements during thermal step stress when the complete medical instrument was working. In this way the performance evaluation of medical ultrasound array transducer has been performed. Being such material innovative in the application, a detailed study of the failure condition regarding the phased-array probe by means of accelerated life testing has been proposed in order to assure its performances and reliability under stress and over time. A comparison of the electro-acoustic measurement results with respect to the conventional probe, soldered with Sn–Pb, has been evaluated. Factors, influencing the soldering process like “thickness of ECA” and “curing temperature” has been analyzed by means of the Design of Experiments (D.o.E.) technique. The research activity has been finished with PhD Thesis, “Experimental studies on new electrically conductive adhesives: characterization, reliability evaluation and innovative industrial applications” (2011).

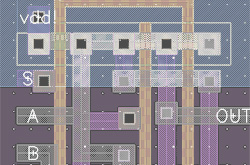

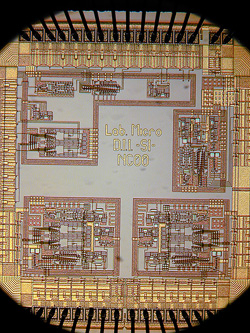

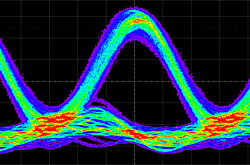

From 2011 to now the research activity has focused mainly on the preparation and characterization of novel materials for conductometric gas chemical sensors at the University of Siena – DIISM – Department of Information Engineering and Mathematics. The study has involved the characterization of prototype sensors with metal-oxide (MOX) sensing layer under different concentrations of nitrogen and air (carrier gases) and CO, NO2, NO, CH3 (target gases). By means of an automatic and versatile measurement system implemented in Electronics, Electrical Engineering and Measurements Laboratory perovskite powders (YCoO3) and defective molecular compositions (YCo0,9O2,7, Y1,1CoO3,3, YCo0,9O2,7, Y0,9CoO2,7) have been characterized in 2011-2012; further perovskite powders with different concentrations of Palladium and Platinum in the lattice (YCo0,95Pd0,05O3 - YCo0,91Pd0,09O3 - YCo0,95Pt0,05O3) and impregnated on the structure surface (YCoO3 + 1%Pd) have been investigated (2012-2013). The research led to the design of a process aimed at the realization of chemical sensors prototypes by means of the screen printer technology with the aim to produce structures suitable for the characterization of the various sensitive materials.

The major hurdles, presented at the beginning of this activity, have been both the high working temperatures of the sensitive powder (even 400 °C) and the need to miniaturize the structure of the sensor in order to obtain a low power dissipation and to key to electronics and tools of automatic measurement system with which characterizations have been done. These difficulties have been overcome initially with finite elements simulations by means of specific 2- and 3-D software and, subsequently by means of the integration of previous studies with experimental tests in temperature, which led to the selection and choice of certain materials, such as silver, palladium and platinum inks/pastes for the realization of electrical connections. The preparation and realization of the sensitive film, starting from the powders, have been the subjects of the research with the aim to improve the adhesion of the sensitive film on the ceramic substrate in order to optimize the performance, the response stability and the reliability over time. Ad hoc organic lattice has been chosen and synthesized; the addition of glass and ceramic frits have guaranteed a better reliability of the sensors, and a satisfactory stability and conservation in time of the chemical-physical characteristics. Cycles for the powders curing have been implemented and developed.

Sport

Francesco Bertocci was a marvellous basket player serving the Meridien Monsummano basket team (B Italian League). His personal page is still available at: http://pallacanestro.webnode.com/products/francesco-bertocci/. His current price on the market is estimated about 1.000.000 euros. Recently, he won the Best Basket Player prize 2014 organized in the LEEME laboratory, beating Mons. Marco Tani in a free throw match, using the laboratory rubbish bin and a paper ball.